Fasciatrice automatica

TECHNICAL SPECIFICATIONS

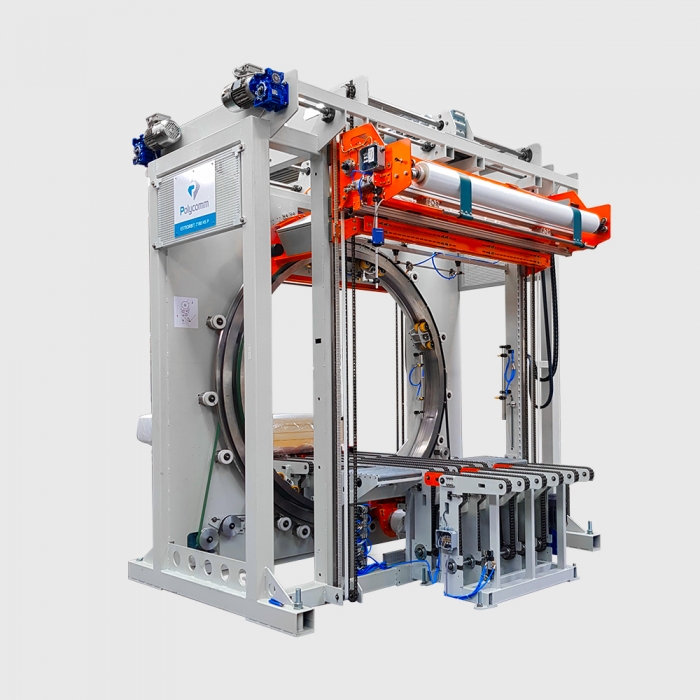

Machine for the packaging of long packages by means of orbital spiral wrapping with stretch film.

Internal conveyor

Located inside the orbital machine.

Width mm. 700 - Length mm. 1670 with 5 branches of motorized chain with inverter for adjusting the feed speed.

Solidarity with the machine.

It supports the neck during the packing and transit phases.

Head / tail cover system

Positioned respectively for the loading and unloading of the machine.

The system consists of a main moving head in which the consumable reel destined to cover the head / tail is positioned, the film unwinding rollers, the sealing and cutting system.

The mobile gripper is placed on the same guide system but with independent drive.

The head / tail covering system provides for an automatic phase of approaching the mobile head to the top of the neck with unrolling of the film flap which will carry out the covering by means of the mobile clamp and subsequent cold cut with translating blade.

This methodology allows to obtain two advantages:

- reduction of film consumption, dosing it according to the single package;

- ease of reel change: the heads descend to the level of the transport plane

Electric management panel

Power supply 400V 3 phases, earth and neutral.

Rated power 25 kW.

Automation for the correct operation of all parts of the line.

Panel for parameter and recipe settings.

Viewing anomalies and troubleshooting.

Siemens panel, Siemens S7-1200 PLC

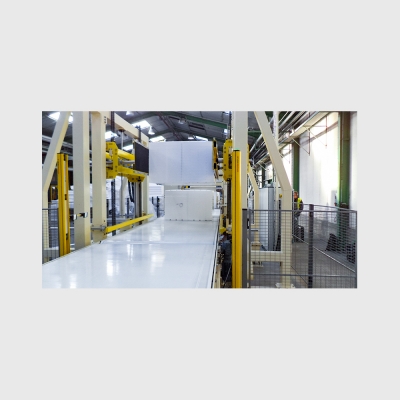

Inlet / outlet conveyors

Connection conveyors with the existing plant equipped with drawbridges for the operation of the head / tail packing system.

Feed speed managed by inverter.

DRL option for fifth wheel rotation

Motorization of the fifth wheel by high performance SEW Eurodrive servomotor.

It guarantees higher performance than a standard motor, allowing quick starts / stops and precise positioning

Pre-stretch option without sliding contacts

Technology based on the use of a high-performance servo drive combined with a mechanical transmission of motion to the pre-extension rollers which eliminates sliding contacts.

Machine downtime reduced to ordinary maintenance and economic advantage on the wear components of the sliding contact

Regenerative sew driver option

Equipping the machine with SEW Eurodrive drives in regenerative configuration.

Multiple advantages are obtained such as:

- increase in machine performance estimated at 5%;

- energy saving thanks to the recovery of the residual energy that is differently dissipated (about 10%);

- reduction of the spaces occupied in the electrical panel;

- less residual heat to be dissipated in the electrical panel;

- possibility of remote access to the individual system nodes.

Foam unwinder support option

Support for Foam reel with manual unwinding independent from the winder placed at the entrance to the plant

Electrical panel components option for existing machines

Integration in the electrical panel of the machine of the drives and of the input / output modules for the management of the existing components of the system.

Panel pc + remote assistance option

Replacing the Touchscreen operator panel with an industrial panel PC.

The power of the PLC is combined with that of a Personal Computer, gaining machine flexibility such as, for example, interfacing with management systems, labelers, remote assistance, weighing systems and more.

Teleservice

Remote remote assistance router

Remote pulpit

Control station hosting all the man-machine interface devices suitable for the operation of the system

Motorization option sew

Increased machine reliability by mounting SEW Eurodrive gearmotors only.

Labeler

Automatic machine for printing and applying customized labels showing the desired data relating to the packaging

Side block positioner

Automatic machine for the positioning of the lateral protection blocks.

Consisting of a multi-row warehouse of blocks with pneumatic dispenser on the gripping and positioning device.

The gripping element is equipped with vertical translation for correct positioning in height and horizontal translation for approaching the neck. Once the positioning has been carried out, a pneumatic cylinder interlocks the block with the lip to be protected.

Minimum requirements for the package to be packed:

- pack height not less than 500mm;

- lip facing down;

- time between one positioning and the next not less than 20 sec;

- setting of the position by the operator or transmitted to the machine via bus.

- Hot gluing system for lipless panels

Rotating ring with useful passage diameter mm. 2180

Film reel rotation speed adjustable by inverter

Automatic film hooking and cutting unit

Stretch film reel height 500 mm

Worktop height mm. 910

380 V three-phase power supply + Earth + Neutral

Compressed air: pressure 7 bar; consumption 300 NL / min

1 motor pre-stretch device

OPERATIONAL FEATURES

Minimum package width <B min> 700 mm

Maximum package width <Bmax> 1100 mm

Minimum pack height <H min> 700 mm

Maximum pack height <H max> 1200 mm

Minimum package length <Lmax> 1200 mm

Minimum product weight 100 Kg

Maximum product weight 1500 Kg

Average productivity 8 meters / minute

DICHIARAZIONE DI CONFORMITA 2006/42